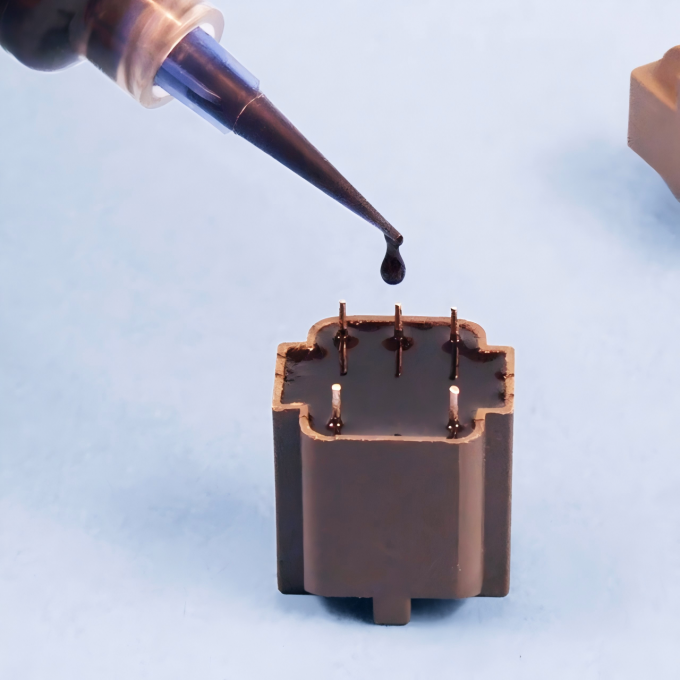

EP3108 series Clear epoxy potting adhesive is a room temperature/heat curing epoxy resin adhesive. This two-component epoxy adhesive is designed for potting, protecting electronic products that require high strength or confidentiality.

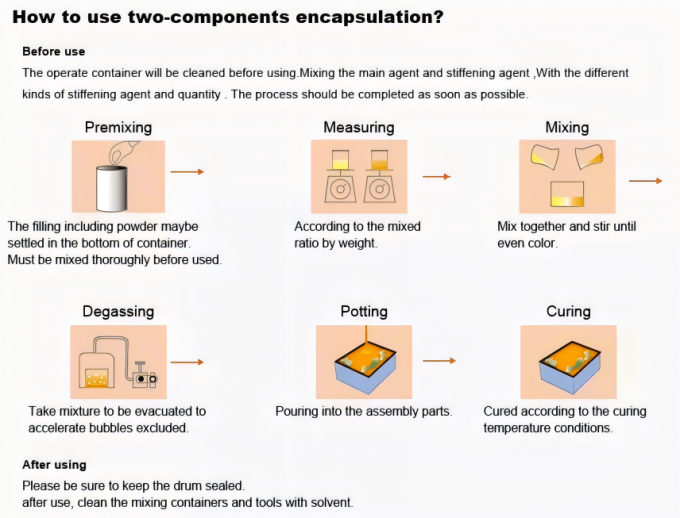

The EP3108 series of epoxy potting adhesives cure without heat. After thoroughly mixing component A and component B by weight ratio, the product cures within a certain time to form protection.