All Products

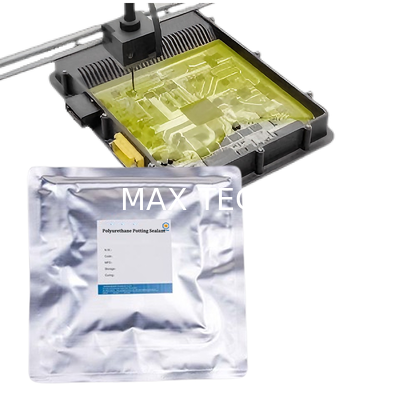

High Thermal Conductivity White PU Potting Adhesive for PCB/LED - Waterproof, Shockproof, Fast Curing Sealant

Product Details

| Adhesion | Excellent Adhesion To Metals, Plastics, And Ceramics | Curingtime | 24 Hours At Room Temperature |

|---|---|---|---|

| Waterresistance | High | Hardness | Shore A 50-70 |

| Application | Potting And Sealing Electronic Components | Dielectricstrength | 20 KV/mm |

| Viscosity | 5000 - 7000 Cps | Materialtype | Polyurethane |

| Chemicalresistance | Resistant To Oils, Solvents, And Chemicals | Color | Black / Clear / Custom Colors Available |

| Shelflife | 12 Months When Stored In Cool, Dry Place | Productname | Polyurethane Potting Sealant |

| Mixingratio | 1:1 (base To Hardener) | Temperatureresistance | -40°C To 120°C |

| Apperance | Clear | Samples | Yeah |

Product Description

We Supply Free Samples. OEM & ODM are Welcomed. we can do your logo and Brand

PUR1660 High Performance Optically Transparent Polymers for LED Encapsulation

High Thermal Conductivity White PU Potting Adhesive for PCB/LED - Waterproof, Shockproof, Fast Curing Sealant

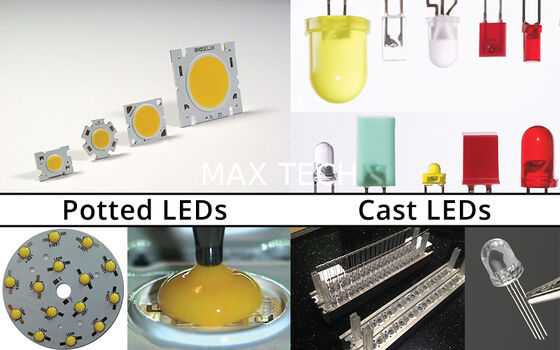

Optically clear polymers allow light to pass through them without significant distortion. These materials are commonly used to protect LED circuitry from the harsh demands of outdoor environments, heat generation, liquid exposure, and hazardous environments. Our LED encapsulating materials are used to protect electronic circuitry in a variety of applications, including:

* LED drivers

* Power supplies

* LED lamps with integrated drivers

* Outdoor LED displays

* Automotive lighting

* Decorative and outdoor strip lighting

* Pool & spa lighting

* Emergency lighting & signaling

* LED drivers

* Power supplies

* LED lamps with integrated drivers

* Outdoor LED displays

* Automotive lighting

* Decorative and outdoor strip lighting

* Pool & spa lighting

* Emergency lighting & signaling

Specialist LED resin designed to offer the LED and PCB environmental protection while maintaining optical clarity and colour even after prolonged UV exposure.

Specification

Product Description

Description

PUR 1660A/B is a two-component-free-free room temperature or a heat-curable polyurethane gel for two-component sealing and filling. The raw material does not contain heavy metals, green environmental protection, wide process, high finished physical properties, and good binding properties. The room temperature and heating curing can be deeply cured, and the two groups have a good fluidity after mixing, the hardness is extremely low, the flexibility is excellent, and the low temperature resistance is excellent. It is used in communication equipment,transformers, control power, ignition Pouring and potting of controllers, electronic sensors, medical insoles etc.

Typical Applications

It is used in communication equipment,transformers, control power, ignition Pouring and potting of controllers, electronic

sensors, medical insoles etc.

sensors, medical insoles etc.

Optical grade transparent polyurethane potting is a liquid resin used to encapsulate electronic components, particularly LEDs, for protection and aesthetic appeal.

Optical grade transparent polyurethane potting is a liquid resin used to encapsulate electronic components, particularly LEDs, for

protection and aesthetic appeal. These compounds are formulated to be optically clear, meaning they do not yellow from UV exposure, and provide protection from environmental factors like moisture, dust, chemicals, and physical impact. They are available in two-part systems that can be poured or cast to protect and stabilize electronic assemblies.

protection and aesthetic appeal. These compounds are formulated to be optically clear, meaning they do not yellow from UV exposure, and provide protection from environmental factors like moisture, dust, chemicals, and physical impact. They are available in two-part systems that can be poured or cast to protect and stabilize electronic assemblies.

Key Features

* Low viscosity, strong operability *Low hardness and certain toughness *Excellent electrical insulation, stability * Good waterproof, moistureproof, very low water absorption * Good adhesion to most metals and plastics

* High transparency: Formulated to remain crystal clear and prevent yellowing from UV light exposure, making it suitable for applications where visibility is crucial.

* Environmental protection: Shields electronic devices from dust, moisture, chemicals, vibration, and impact.

* Mechanical stability: Enhances the mechanical stability and dielectric strength of electronic parts.

* Versatile application: Can be used for both protective and decorative purposes, such as potting and encapsulating LEDs, electronic devices, or for doming labels and badges.

* Easy processing: Often available in a simple 1:1 mix ratio with low viscosity, which aids in application and allows for excellent penetration and air release.

* Environmental protection: Shields electronic devices from dust, moisture, chemicals, vibration, and impact.

* Mechanical stability: Enhances the mechanical stability and dielectric strength of electronic parts.

* Versatile application: Can be used for both protective and decorative purposes, such as potting and encapsulating LEDs, electronic devices, or for doming labels and badges.

* Easy processing: Often available in a simple 1:1 mix ratio with low viscosity, which aids in application and allows for excellent penetration and air release.

Packing Specification

PUU1660 A/B polyurethane potting compound Order Code: A: 2KPU2072; B: 2KPU2073 A: 18kg/ iron drum or 200kg/ iron drum B:

18kg/ drum or 200kg/ drum Other colors need to be customized Other packaging needs to be customized This glue is not dangerous and can be transported as a general chemical .

18kg/ drum or 200kg/ drum Other colors need to be customized Other packaging needs to be customized This glue is not dangerous and can be transported as a general chemical .

Transport &Storage

● Unused raw materials should be stored in a well-sealed bucket to avoid moisture intrusion and affect the quality of raw materials. The opened materials should be kept sealed and used up as soon as possible. ●It is recommended to store in a cool area, away from direct sunlight; ?Storage temperature: 10-30℃, A material storage period of 12 months; Material B is 6 months..

How to use a) Use: The raw material of material A contains functional resin, before taking the material, pay attention to the detection package is intact. After the filler is completed, it is sealed to prevent the original packaging to prevent excess of moisture. After the rubber is exposed to the air time, it may cause the AB material to bubbling the phenomenon. If conditions permit, the original packaging of material A can be placed in an insulated environment above 30 degrees. b) Operation: B material is exposed to water absorption in the atmosphere, and the phenomenon is turbid until agglomeration, and the A material also needs to be stored, so as not to solidify excessive bubbles. The environment in which the curing process needs to control the humidity as low as possible, and the relative humidity should not exceed 60%. c) Preheat: The cast device is taken from 70 to 80 ° C for 1 to 2 hours. It can also reduce the temperature to extend the heating time to remove the device moisture. At low temperatures The viscosity will increase. The material can be preheated to 25℃ to 45℃ for easier use. d) Defoulating: Vacher for A B buckets, simultaneously, to ensure that the A B glue is vacuum- free. e) Pouring: Put the mixture into the device through a static mixer, the gel time is approximately within 60 mins. f) Curing: 25℃ / 24 hrs. The environmental humidity should be controlled at <70%, and the temperature is low to extend the curing time as appropriate

Welcome to talk more with us if you have any inquiry.

Related Products

Related Products

Junction box silicone gel

One Part Silicone Sealant of electronic component

Thermal Conductivity Silicone Potting Sealant

Company Profile

Our Advantages

Certifications

Exhibition

Packing & Delivery

FAQ

Q:How long can I get a quote

A:The quotation can be provided no longer than 24hours on condition that we know all detailed requirement.

Q:Do you accept private Label?

A:Yes. ODM & OEM are Welcome.

Q:Can I get a samle before order?

A: Of course. Generally, we provide 1-3 pieces free samples for quality testing and the courier fee be born by customers. Thanks for your understanding.

Q:Do you have MOQ.

A:Yes, Generally ,MOQ is 1000pcs or 1000kg.

Q: How long will finished my order?

A: It’s depend on your order quantity.

Generally, Our production time is 10-15 days after get the payment.

Q:How to find the suitable sealant?

A: Please let me know your application purpose,substrate, application method and all your requirements. We would like give you a better recommendation.

A:The quotation can be provided no longer than 24hours on condition that we know all detailed requirement.

Q:Do you accept private Label?

A:Yes. ODM & OEM are Welcome.

Q:Can I get a samle before order?

A: Of course. Generally, we provide 1-3 pieces free samples for quality testing and the courier fee be born by customers. Thanks for your understanding.

Q:Do you have MOQ.

A:Yes, Generally ,MOQ is 1000pcs or 1000kg.

Q: How long will finished my order?

A: It’s depend on your order quantity.

Generally, Our production time is 10-15 days after get the payment.

Q:How to find the suitable sealant?

A: Please let me know your application purpose,substrate, application method and all your requirements. We would like give you a better recommendation.

As our suggestions of the sealant choose:

As a manufacturer, we would like to share with you what we have learned about the different types of potting compounds and their

characteristics. The potting compounds on the market vary in viscosity, requirements for cure conditions, among other factors.

Compounds such as polyurethane, silicone, and epoxy are widely used in a variety of applications. 1. Silicone Potting Compounds

are soft and flexible, silicone potting compounds and encapsulating materials possess a good level of elongation.Silicone potting

compound can also withstand a wide range of temperatures. Most silicone materials are able to operate at temperatures between

-40°C and 200°C. 2. Epoxy potting compounds generally perform as a better adhesive, high-temperature resistance, and chemical

resistance and have better adhesion to a wide variety of substrates and typically do not need primers. 3. Polyurethane Potting

Compounds generally have better flexibility, elongation, and abrasion resistance. 4. Acrylic Potting Compounds are UV and

heat-hardening materials, with fast hardening, adequate chemical resistance, and clear appearance.

As a manufacturer, we would like to share with you what we have learned about the different types of potting compounds and their

characteristics. The potting compounds on the market vary in viscosity, requirements for cure conditions, among other factors.

Compounds such as polyurethane, silicone, and epoxy are widely used in a variety of applications. 1. Silicone Potting Compounds

are soft and flexible, silicone potting compounds and encapsulating materials possess a good level of elongation.Silicone potting

compound can also withstand a wide range of temperatures. Most silicone materials are able to operate at temperatures between

-40°C and 200°C. 2. Epoxy potting compounds generally perform as a better adhesive, high-temperature resistance, and chemical

resistance and have better adhesion to a wide variety of substrates and typically do not need primers. 3. Polyurethane Potting

Compounds generally have better flexibility, elongation, and abrasion resistance. 4. Acrylic Potting Compounds are UV and

heat-hardening materials, with fast hardening, adequate chemical resistance, and clear appearance.

Max Tech Do the PU , Silicone, MS, Epoxy

For Automotive , Construction and Electronic Industry.We also do related tools, machines & accessories.

For More Information

Welcome to talk more with us.

Have a nice day.

For Automotive , Construction and Electronic Industry.We also do related tools, machines & accessories.

For More Information

Welcome to talk more with us.

Have a nice day.

Recommended Products