Silicone Gels

Protect Circuits and Interconnectors from High Temperature and Mechanical Stress with Silicone Gel

Contact me for free samples and coupons.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Materials | Silicone Resin | Color | Clear/ Transparent |

|---|---|---|---|

| Part | Two Part | Sample | Free Samples |

| Packing | 20kg Per Set | Application | Electrical Insulation And Moisture Protection For Low-voltage Applications, Particularly Suitable For Insulating Cables And Wires In Junction Boxes. |

| Name | Waterproofing Silicone Gel | Product Name | Two-component Silicone Gel |

| Appearance | Transparent Liquid | Report | RoHS REACH,ISO |

| OEM | Yeah | Keyword | Electric Insulation, Good Waterproof And Moisture Resistance , Silicone Gel |

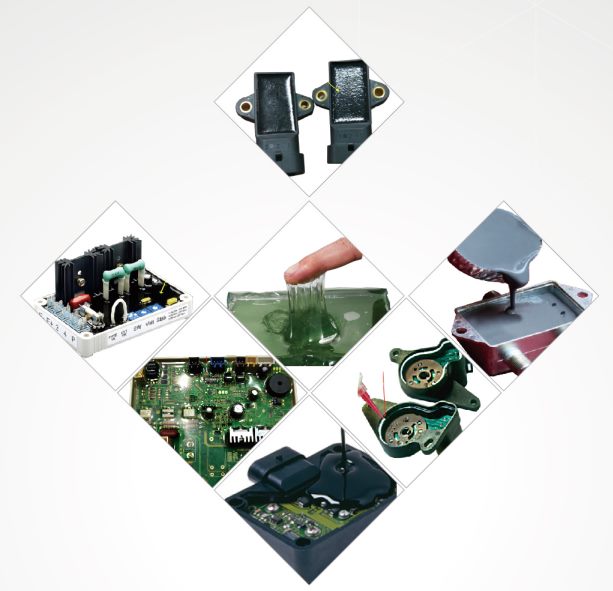

| Usage | Encapsulation Of Various Modules, Semi-conductor, IGBT, Automotive ECU Module, IC Chip, Weighing Sensor, Waterproof Connector. | Advantage | High Quality, Easy To Apply |

high quality electrical insulation Blue waterproof cable junction box silicoen gel

6606 is a transparent two-component self-healing silicone gel. After curing, it forms a special soft material that is buffered and automatically recovered. It is designed to insulate circuit boards from moisture and other harmful contaminants and to provide insulation against high voltages. Another use is to provide stress relief to protect circuits and interconnectors from high temperature and mechanical stress.

l 1:1 addition molding, strong viscosity

l High elongation; Excellent flexibility, eliminating mechanical stress

l Very low oil permeability after curing, excellent resistance to toxicity

l High temperature electrical insulation is excellent, to provide protection against high pressure

l Long-term use temperature range -50-220℃

l Excellent aging resistance and weather resistance

l Excellent waterproof, anticorrosive, moisture-proof, chemical medium resistance

l It can be used in semiconductor modules, sensors, etc

Typical applications

Power semiconductors, electronic sensors, MEMS Top Coating, automotive ECU integrated modules and other packaging protection IC chips, undersea fiber pooping and so on.

Pre-curing characteristics

| Component A | Component B | |

| Appearance | Clear fluid | Clear fluid |

| Viscosity,25 ° C CPS | 1000±200 | 1000±200 |

| Specific gravity, g/cm3 | 0.99 | 0.99 |

| Mix ratio | A: B = 100:100 weight ratio | |

| Viscosity after mixing | 1000±200 cps | |

| Operating time after mixing | 25℃ for 120-180 minutes | |

| Hardening conditions | 24 hours at 25℃ or ≤60 minutes at 80℃ | |

| Appearance | Colorless clear gel | |

| Needle penetration,1/10 mm | 75±10 | |

| Thermal conductivity, W/m.K | 0.22 | |

| Dielectric strength (KV/mm) | 25 | |

| Volume resistance (Ω·cm) DC500V | 1.0×1015 | |

| Loss factor (1 MHz) | <0.001 | |

| Dielectric constant (1 MHz) | 2.8 | |

| Use temperature range | - 60 ∽ 260 ℃ | |

| Temperature range for long-term use | -50 ∽ 220 ℃ | |

![]()

![]()

∎Packing Specification

●Part A—10 KG/Bucket

●Part B—10 KG/ Bucket.![]()

![]()

∎Transport &Storage

● When stored at or below 25°C in the original unopened containers, this product has a usable life of 12 months from the date of production. Sampling test is necessary for products which exceed shelf life before taking use.

It’s non-dangerous goods, can be transported as normal chemicals, CAUTION leakage during transport.

.∎Directions for Use

- Mix Part A and Part B by 1:1 mass ratio, after evenly mixed, pouring directly into the components or modules as per requirements.

- Still the potted component to let out the bubbles. It can be heat cured, about 30mins in 80°C. It needs about 4-5hours cured under room temperature. Require 24 hours to achieve surface without obvious oil layer.

Vacuum defoaming can improve the performance of cured product. Seal the remaining products tightly after use. Low temperature will slow the curing speed; heat curing is recommended. It's hard for SI8715 to cure if contact with sulfur, amine or Sn

∎Attention of operation

●Keep away from Children

●Avoid contact with eyes and skin. If contact with your skin, scrub first with soap water or alcohol, then rinse with water. If contact with your eyes, rinse with plenty of water, and seek medical treatment immediately.

● It is forbidden to build on the surface of the wet substrate.

∎Safety Operation Data

MSDS isn't included here. Please read TDS, MSDS and label carefully before operation. You can get MSDS from MAXTECH or other distributors, or mail to service center maxtech@shmaxtech.com

∎Warranty and Liability

All product properties and application details based on information believe to be reliable and accurate. But you still need to test its property and safety before application. The advice we supply don't apply in any circumstances. MAXTECH don't make assurance of any other applications outside the specification until MAXTECH supply a special written guarantee. MAXTECH is only responsible to replace or refund if this product is defective within the warranty period stated above. MAXTECH makes it clear that will not be liable of any accidents.

With more than 10 years of effort & premium quality, And we have won the approval of domestic and international customers. Especially in Southeast Asia, South America, North America, and Africa.

Choose MAX TECH, a trusted long-term partner.

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

Silicone Gels

A:Normally the delivery time is about 15 days depend on quantity required after deposit. Except public holidays.

Q: What is the minimum order quantity?

A: Normally our MOQ is 1000kg, For the first time, Small order is welcomed, we will support it.

Q: How to get the samples?

A: Yes , 100-200g free samples are available. Delivery cost will be paid by clients.

Q: How long can I get a quote?

A: The quotation could be provided within 24 hours once we know all detailed requirements.

Q: Can you provide OEM service?

A: Yes, OEM & ODM are welcome. Private Label We can accept.

Q: How can you guarantee the quality?

A: We have rigorous quality test system, from raw materials to finished products, the materials must be inspected and signed by QC staff.

resourcing of related products.

Any inquiry, welcome to talk more with us , contact us sally, sally@shmaxtech.com; +8618321208486